M1.1 Design Project - 2022

Project name: “W.E.E. : Water Emitting Entity”

Co-designers: Midas Zegers and Dia Samit

Grade: P

Expertise Areas: TR / US / CA

Project description

This project proposes a way of using algae to filter air polluted rainwater. Algae feed of toxic substances in water, which makes the water suitable for human consumption.

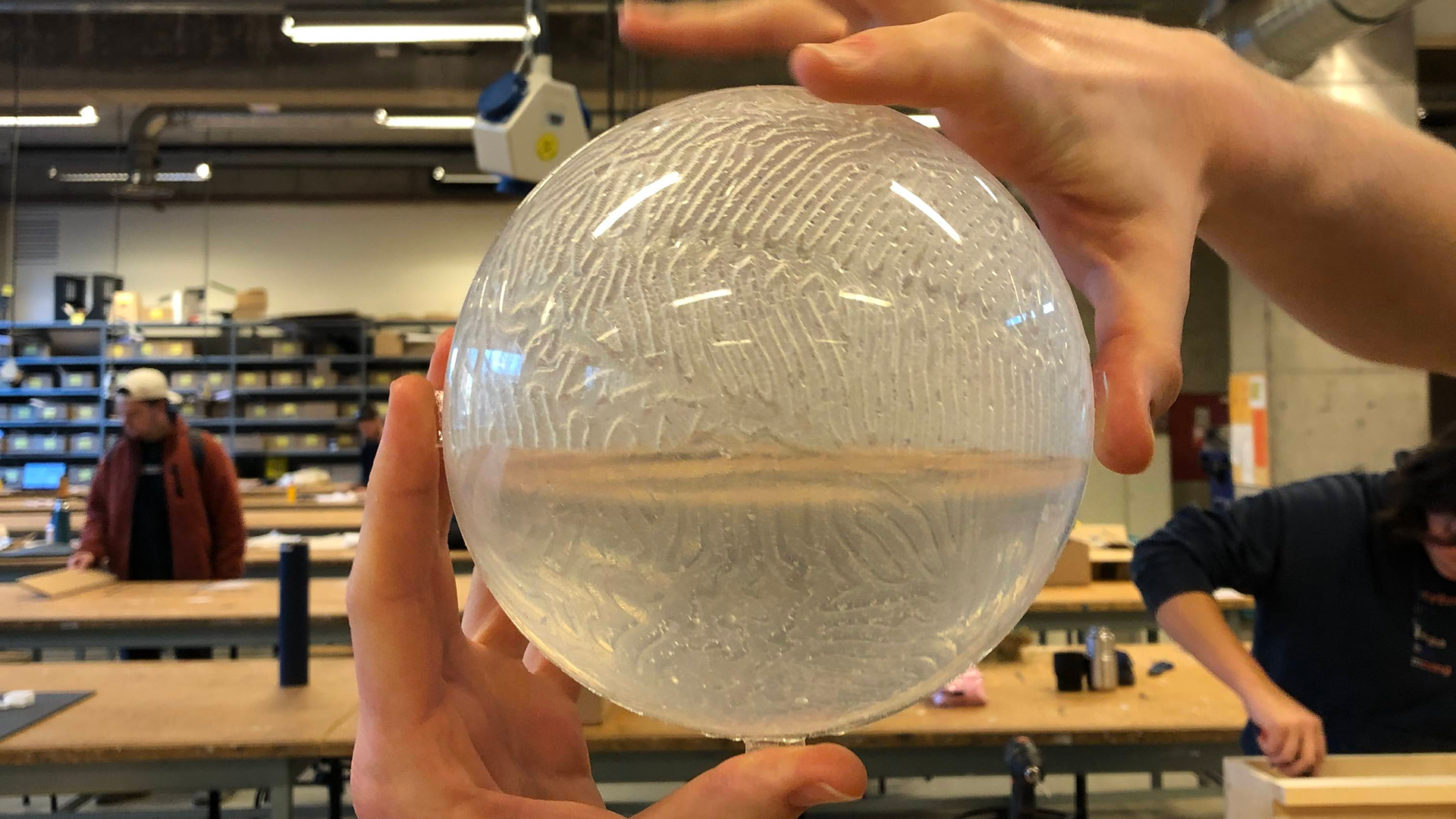

W.E.E. is a water purification system which focusses on human and algae interaction through a Material Driven Design process (Karana et al., 2015). Several silicon semispheres house an algae colony. Each sphere was textured in a digitally crafted way so algae were able to stick to them. The rainwater would flow into the system and land in the first semisphere. Here, the algae would purify the water for the first time. When you squeeze in the silicon semisphere, the clearer water would flow through a pipe system, landing in a new semisphere for the second filtering stage. This process happens four times after which you can retrieve the water from a tab at the bottom of the system.

Reflection

This project was my first experience with more-than-human-design, as I usually follow a human-centered-design process. For me, the direct feedback or responsiveness in more-than-human design was lacking which made me realise how much I like to work with human users and their nuanced way of communication. Furthermore, I also learned how a material driven design process works. This process allowed me to explore new materials, their characteristics and possible concepts, and process them in a structured manner.

During this project I also developed my prototyping and showcase skills. This system was on a larger scale than I am used to. Furthermore, this project challenged me to use ready-made products as I usually fabricate all pieces from a prototype by myself.This made me realise I do not have to reinvent the wheel, increasing efficiency and reliability, using the parts at hand.

When it comes to materials and manufacturing, several materials were explored during the process. Various plastics were used. The silicon semispheres were casted and secured to the main panel using an acrylic slotting mechanism. Furthermore, there were some tests done with the ultrasonic welding of plastic sheets.

Karana, E., Barati, B., Rognoli, V., & Zeeuw Van Der Laan, A. (2015). Material driven design (MDD): A method to design for material experiences. International journal of design, 9(2), 35-54.https://re.public.polimi.it/handle/11311/979536